rockwell hardness tester the b scale uses|rockwell c hardness scale examples : specialty store The Rockwell hardness B scale used for soft or mild metal materials, is the second most common hardness scale in the testing field. The information provided in this article is likely to be enough for you if you want to proceed with this test for hardness deduction purposes. WEBA emoção de explicar quem foi Joelmir Beting - Notícias do Palmeiras - Nosso Palestra. Notícias. Sub-17. A emoção de explicar quem foi Joelmir Beting. João Gabriel Falcade 29 de novembro de 2017 15:21 2min .

{plog:ftitle_list}

Resultado da 3 dias atrás · Cara kerja aplikasi hack slot ini adalah memperdaya server dar game slot pragmatic yang dituju kemudian masuk pada celah. Hack slot pragmatic apk ini dianggap bisa memperbesar kemungkinan menang atau mendapat jackap sehingga pemain tidak kehabisan modal.

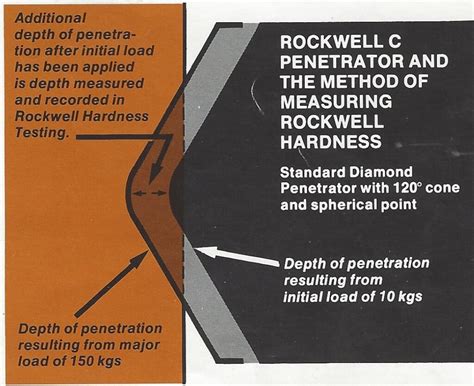

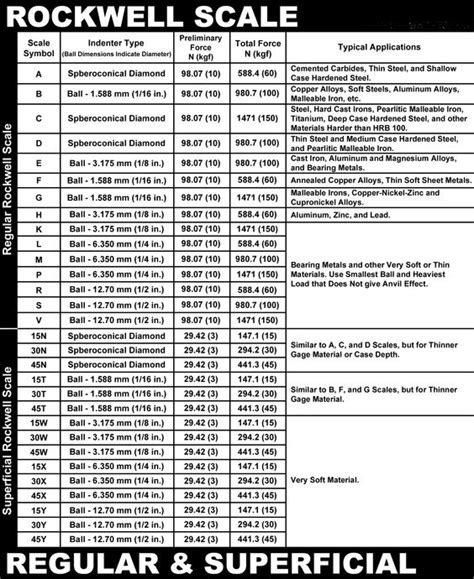

Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a .A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) and Rockwell C (HRC). This article compares two types of Rockwell hardness to help you find the most ideal of the two for your hardness testing and conversion needs.The Rockwell hardness B scale used for soft or mild metal materials, is the second most common hardness scale in the testing field. The information provided in this article is likely to be enough for you if you want to proceed with this test for hardness deduction purposes.

The Rockwell B-scale can be used in the case of softer materials such as brass, aluminum, and softer steel. It utilizes a hardened steel ball as an indenter along with a 100kg weight in order to derive a value, which is expressed as ‘HRB’. . It is mandatory to control the speed of the indentation while measuring in the Rockwell hardness .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics.

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf . 1822: The Mohs scale for mineral testing is invented. This is a ten-point scratch hardness scale in which each material can be scratched using the .There are several alternative scales, the most commonly used being the "B", and "C" scales. Both express hardness as an arbitrary dimensionless number. The B-scale is used for softer materials (such as aluminum, brass, and softer steels). It employs a hardened steel ball as the indenter and a 100kg weight to obtain a value expressed as "HRB".

feuchtigkeitsmessgerät ab wann nass

The scale follows an even subdivision of 0.002 mm (2 µm), so that reaching half the reference depth also corresponds to half the maximum hardness value (Rockwell hardness value 50). When diamond cones are used, the Rockwell .Each different Rockwell scale uses a different and load weight to test the material. The results of the test are given a code that includes HR and then the scale letter, i.e. HRA or HRB. To evaluate hardness, Rockwell hardness testers use a differential-depth method. The test consists of placing an on the material, then applying a minor load .Each Rockwell hardness scale is identified by a letter designation indicative of the indenter type and the major and minor loads used for the test. The Rockwell hardness number is expressed as a combination of the measured numerical hardness .No wonder, Rockwell hardness testing scales are globally used and are the most popular ones. It is used for static hardness testing of the material. We have described thoroughly in this article the scales of the hardness test. Just follow the standard scale tables and rules to get the accurate values of the hardness of your test material.

The article helps you understand principle and applications of the Rockwell hardness test method. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are; Our History; Why Choose Us . Rockwell superficial scales use lower loads than a regular Rockwell test and are used to test materials too thin or small for the regular . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness . Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time). The majority of applications are covered by the Rockwell C and B scales for testing steel, brass and other metals. However, the increasing use of materials other than steel and brass, as well as thin materials, necessitates a .

Rockwell hardness testing methods are defined in the following standards: ASTM E18 Metals, ISO 6508 Metals, and ASTM D785 Plastics. Skip to content +1 847-295-6500; [email protected] . A recorded hardness number .

Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the .

The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a measuring transducer. The DuraJet, ZHR Touchscreen and ZHR8150CL models are software controlled hardness testing machines with automatic .A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N. Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .Introduction. When manufacturing metal components of any kind, it’s important to have control over the properties of a finished part. To ensure that your finished product meets all the necessary specifications, you might need to perform a Rockwell hardness test on a metal part or test sample at different points during production. It is useful to check the hardness of steel and .

The Diamond Hardness Test is another name for any scale that employs a diamond indenter. Amount of the total test load; B; scale division; and C. The regular and superficial varieties each require the application of nine separate Rockwell scales. i. HRA – This scale utilizes a 120° diamond spheroconical indenter along with a 6-kgf major load .

It’s most commonly used to check the hardness of steel that’s been heat treated. Here’s the process: How to Use a Rockwell Testing Machine. Pick out the penetrator. Usually soft materials like 1018 mild steel will use the Rockwell B scale, which makes use of a 1/16″ rounded steel penetrator with a 100 Kg major load.Rockwell Hardness tester, such as Wilson Model 524T Rockwell Hardness Tester, or equivalent, with diamond brale 120° cone or 1/16 inch diameter carbide ball . When testing on the Rockwell B scale, if the HR value of an indentation exceeds 100 points, change the indenter ball. Make one indentation on a test block to seat the The Rockwell Hardness Tester has many different scales depending on the application of the tester on different materials. There is a total of 30 Rockwell hardness scales available to use for hardness testing and hardness value. The Rockwell Regular Scales Testing use a preload of 10kgf and a major load of 50kgf, 100kgf, or 150kgf.

The ASTM specifies thirty different Rockwell scales, each employing a different combination of test forces and indenter types, which allows the testing Test Procedure of most types of metallic materials and products. When Rockwell hardness is called out by a product standard or specification, the choice of scale is usually specified. In situations where the user must choose .

Rockwell B scale (RHB): This scale is used for testing harder materials, such as brass, mild steel, and annealed copper alloys. The load applied is 100 kgf and the diamond cone indenter is used. . Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell .

understanding rockwell hardness scale

10,001 Nights is a highly volatile slot with great artwork and completely theme-fitting sounds. The theme is not stale and has a lot of potential as we can clearly see from this magical creation that Red Tiger Gaming has made. The win potential fits the title and you can expect wins to go over x10001 your bets.

rockwell hardness tester the b scale uses|rockwell c hardness scale examples